If i had a shop your size i might consider not doing the entire floor in any one method but epoxy or even a acid washed and sealed concrete would be a good base and to use for most of the floor.

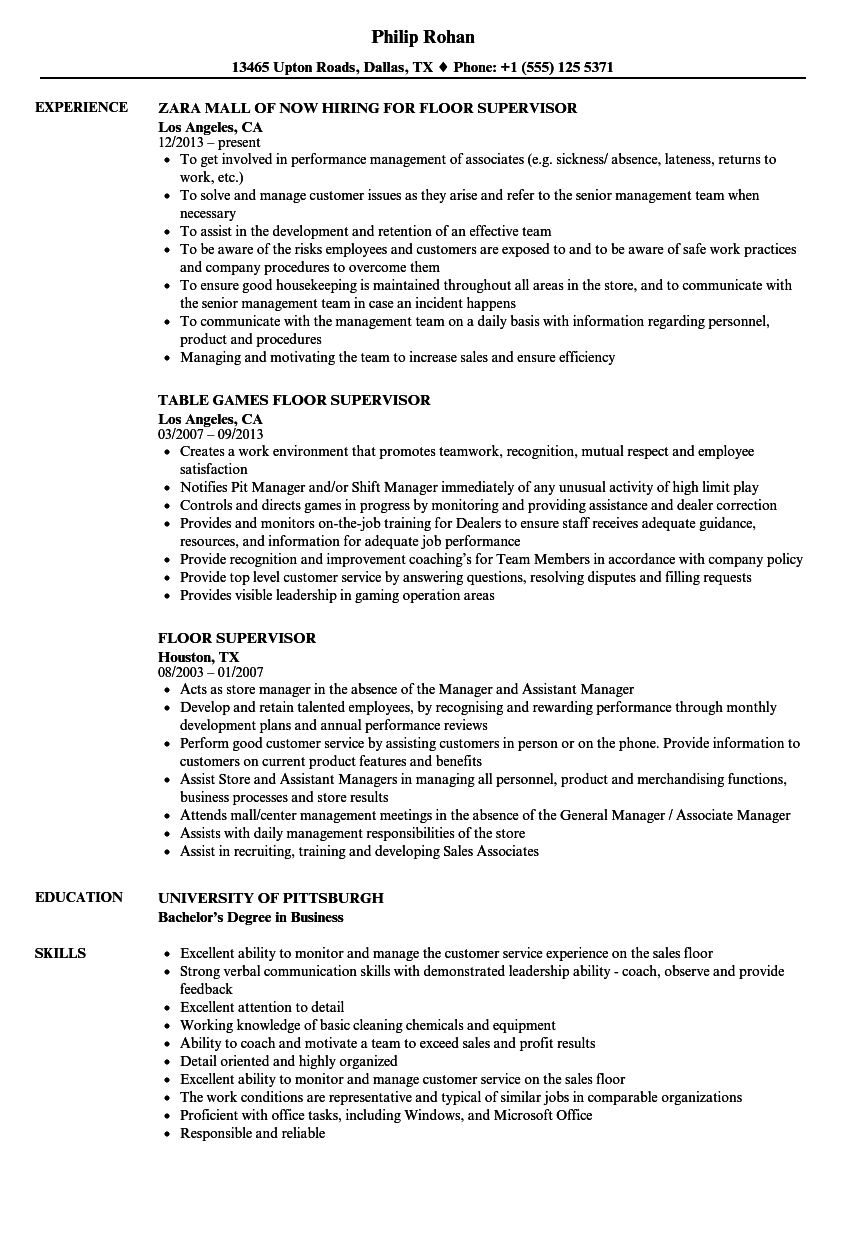

Shop floor manager alternatives.

Shop floor manager can track productivity of each fabricator therefore helping to maintain and organize employees as well as promote where necessary.

To stay competitive it is an expectation that the shop has a formal quality management system in place that is integrated with their shop floor management solution.

Concrete will afford you lots of options and a slab floor will give the next owner of your shop every alternative for using the building too.

Plus you won t have the same freedom as a store manager because a shop floor manager still has onsite bosses to answer to on a daily basis.

The shop floor may include equipment inventory and storage areas shop floor is the place where design specifications are referred machinery and manufacturing equipment are employed for production parts are assembled or some raw material is processed.

Most shops have implemented quality management systems to monitor quality including non conformances and corrective actions.

Ability to stay relevant innovative and competitive without the use of modern technology manufacturing companies are struggling to stay relevant and competitive.

Rust bullet for concrete.

Clintflint january 18 2013 fa5t3r well to some extent you re thinking of the director as being the same job in.

This is another option we really like for shop floors.

The epoxy is a good solution.

The advantage to the open grid is if the work area gets wet the water will drain through the holes and the surface will be less slippery than a flat surface.

4 coats of rust bullet for concrete.

The mesh makes it difficult to move tools with casters around the shop.

The texture hides damage and it is applied really thick.

According to recent research.

Apply to manufacturing manager manufacturing supervisor shop manager and more.

Get your shop floor clean and dry and apply.

Even indoor outdoor carpet floor tiles.

This flooring option is easier on feet than a concrete floor because the rubber mesh material is flexible.

The shop floor is responsible to produce an intermediate or a final product.

Some people will go as high end as an epoxy mortar floor but this is generally overkill.

If i was building my perfect woodshop and i ve daydreamed a good bit about this it would have hardwood floors wide red oak boards.

The rubber in specific areas or if you want wood try cork flooring tiles.